Market Analysis

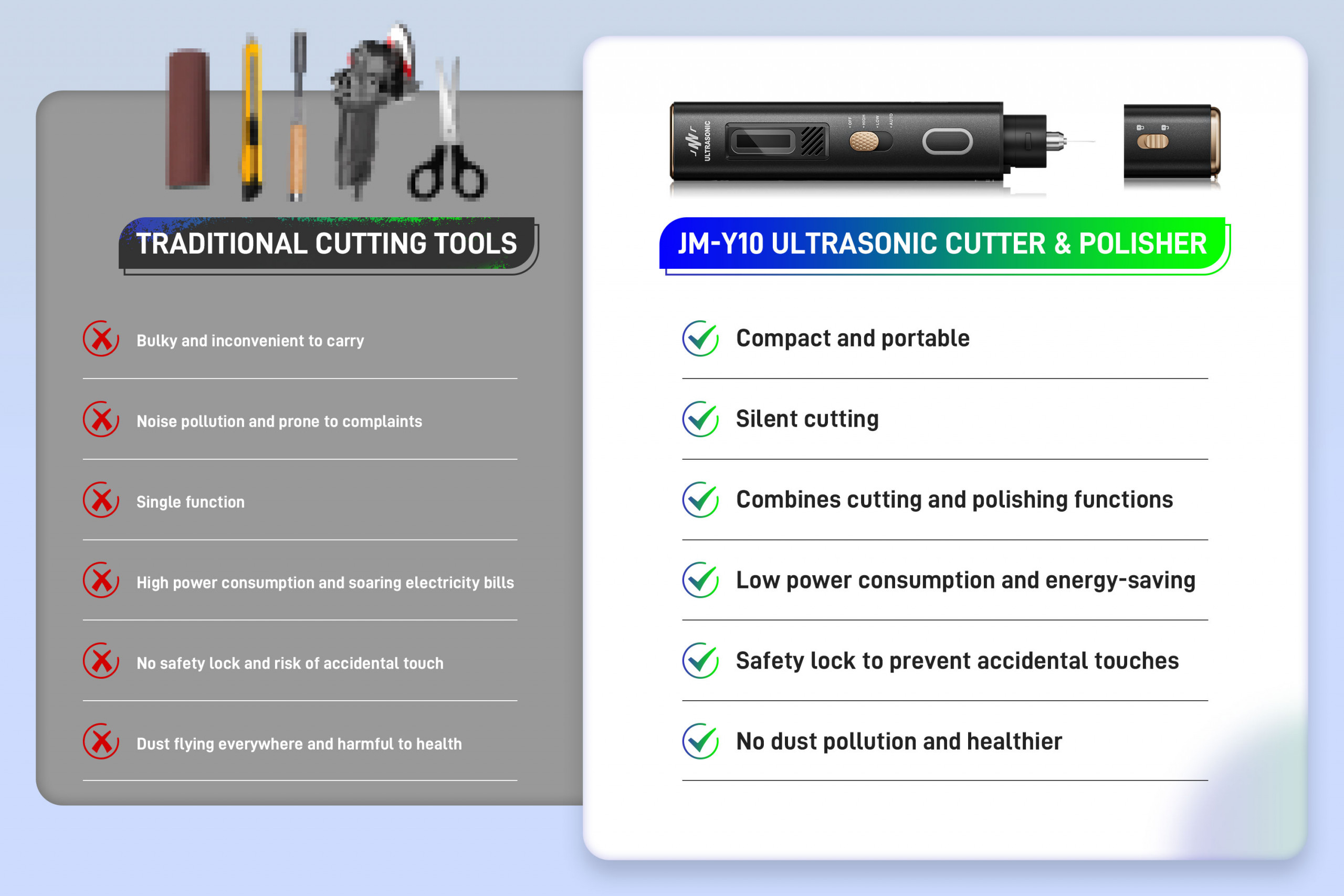

In the cutting-tool market, both traditional tools and civilian ultrasonic cutters face significant challenges:

- Traditional tools: Limited by size, material, and performance. This causes complex operations, low efficiency, and difficulty adapting to complex scenarios.

- Civilian ultrasonic cutters: Many existing models have outdated designs, with a mismatch between performance and price, failing to meet user needs.

These gaps highlight the demand for innovation, creating an opportunity for advanced precision ultrasonic cutter.

Our Innovative Approach

- The ultrasonic cutter boosts efficiency and precision, delivering a new user experience and unlocking market growth potential.

- A compact household tool that replaces bulky traditional tools, perfect for cutting different materials, especially for metal, rubber, plastic, or wood.

- Suitable for industrial production, home crafts, small-scale repairs, and even for 3D print polishing.

In the cutting-tool market, both traditional tools and civilian ultrasonic cutters face significant challenges:

- Traditional tools: Limited by size, material, and performance. This causes complex operations, low efficiency, and difficulty adapting to complex scenarios.

- Civilian ultrasonic cutters: Many existing models have outdated designs, with a mismatch between performance and price, failing to meet user needs.

These gaps highlight the demand for innovation, creating an opportunity for advanced precision ultrasonic cutter.

Design Origin

Global demand for efficient and precise cutting tools continues to rise. Both industrial manufacturing and the civilian market show strong potential. Ultrasonic cutting technology is gaining popularity worldwide. Backed by an experienced R&D team, Jakemy introduces a small civilian precision ultrasonic cutter & polisher.

- How Ultrasonic Cutting Works

Through high-frequency vibration at 40,000 times per second, the blade generates micro-amplitudes that significantly reduce cutting resistance. This enables smooth, stable, and accurate cutting.

- Value & Potential

This innovative precision ultrasonic cutter set combines breakthrough technology with broad market potential. Delivering high performance and a user-friendly design, it meets the needs of professionals and hobbyists alike. Compared with other ultrasonic cutter manufacturers and suppliers, Jakemy provides better precision, stronger stability, and greater ease of use.

For business partners, this DIY ultrasonic cutter helps capture new opportunities, outperform competitors, and build long-term customer loyalty.

Global demand for efficient and precise cutting tools continues to rise. Both industrial manufacturing and the civilian market show strong potential. Ultrasonic cutting technology is gaining popularity worldwide. Backed by an experienced R&D team, Jakemy introduces a small civilian precision ultrasonic cutter & polisher.

- How Ultrasonic Cutting Works

Through high-frequency vibration at 40,000 times per second, the blade generates micro-amplitudes that significantly reduce cutting resistance. This enables smooth, stable, and accurate cutting.

- Value & Potential

This innovative precision ultrasonic cutter set combines breakthrough technology with broad market potential. Delivering high performance and a user-friendly design, it meets the needs of professionals and hobbyists alike. Compared with other ultrasonic cutter manufacturers and suppliers, Jakemy provides better precision, stronger stability, and greater ease of use.

For business partners, this DIY ultrasonic cutter helps capture new opportunities, outperform competitors, and build long-term customer loyalty.

General Uses of Jakemy Ultrasonic Cutter

Our ultrasonic cutter series has powerful functions and a wide range of application scenarios. Whether it is industrial production and processing, or handicraft enthusiasts and model makers, they can find ideal tools here.

1.Cutting Applications

1.Cutting Applications

This ultrasonic cutter can easily handle a wide range of materials with precision and efficiency:

- Carbon fiber boards and acrylic sheets

- Leather, EVA foam, and nylon

- 3D printing support structures and circuit boards

- Paper, corrugated cardboard, and wooden boards/chips

- Plastic pipes, rubber pipes, and more

2.Grinding & Polishing Applications

2.Grinding & Polishing Applications

The upgraded functions support diverse finishing operations:

- Deburring and smoothing of metal surfaces

- Precision finishing of plastic parts

- Wood surface polishing and refinement

- Gypsum model detailing

- Shell surface treatment and finishing

- Post-processing of 3D printed resin models

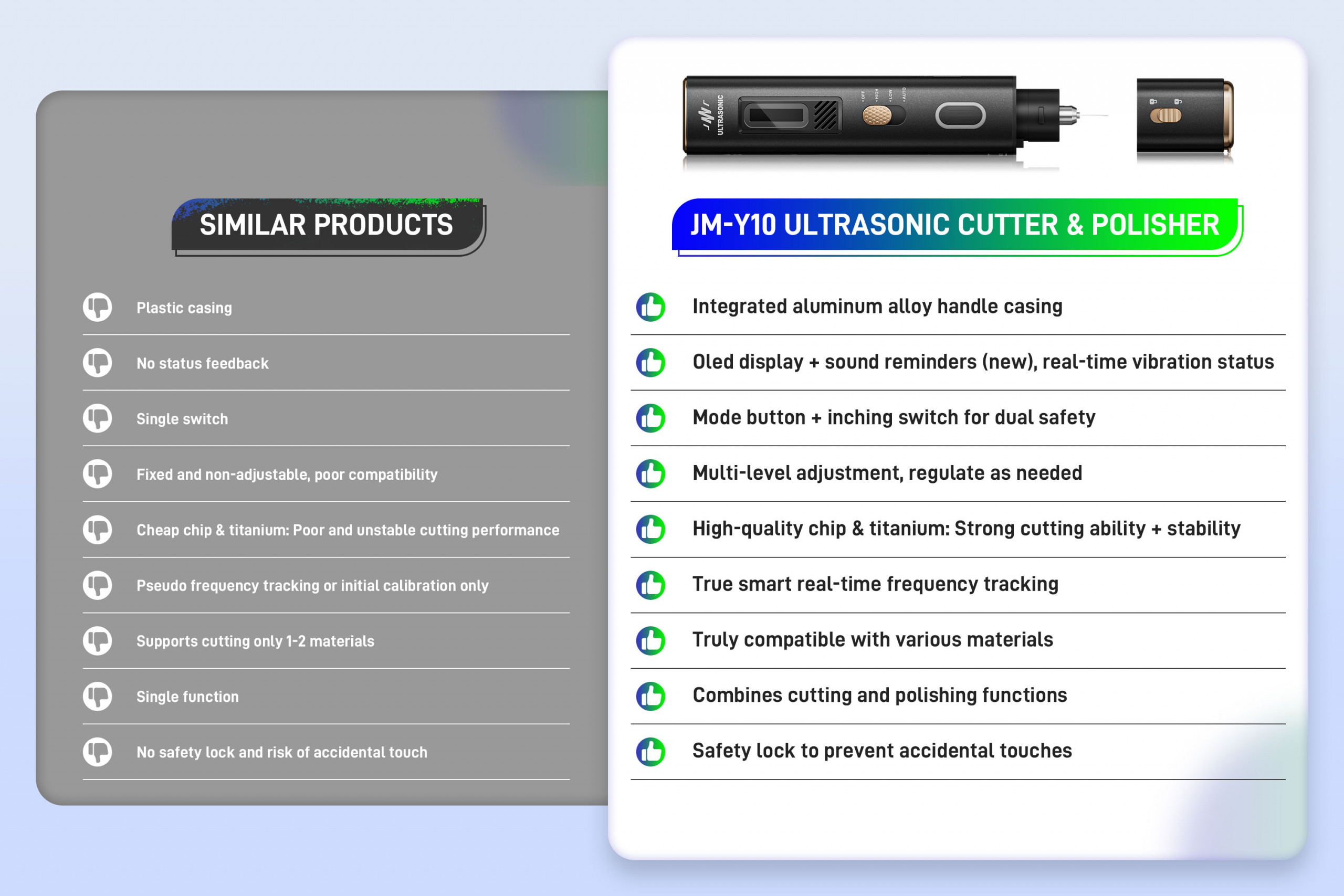

Competitive Advantages of Jakemy Ultrasonic Cutter

Against low – cost rivals, our ultrasonic cutter excels in materials and performance.

Core Advantages

- High-end Configuration: Built with premium wafers, a high-purity titanium alloy horn, and large dual-core ceramic wafers, the Jakemy ultrasonic cutter delivers strong cutting force and long-term stability.

- Wide Compatibility: Smoothly handles diverse materials, such as: metal, rubber, wood, or plastic without jamming or resistance.

- Innovative Design: Compact and portable, this DIY ultrasonic cutter features dust-free, low-noise, and low-power operation with smart safety protection. Outperforms traditional tools comprehensively.

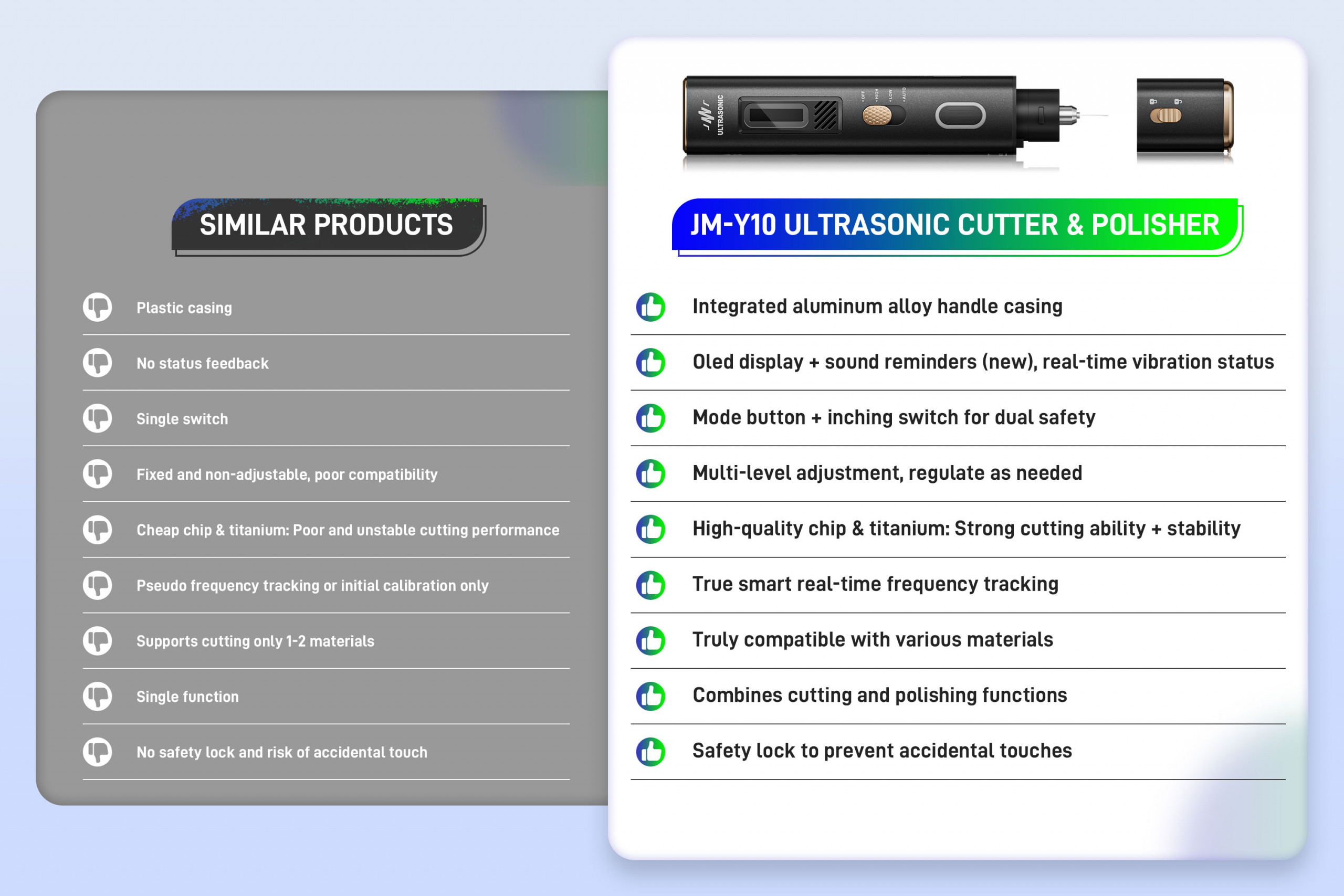

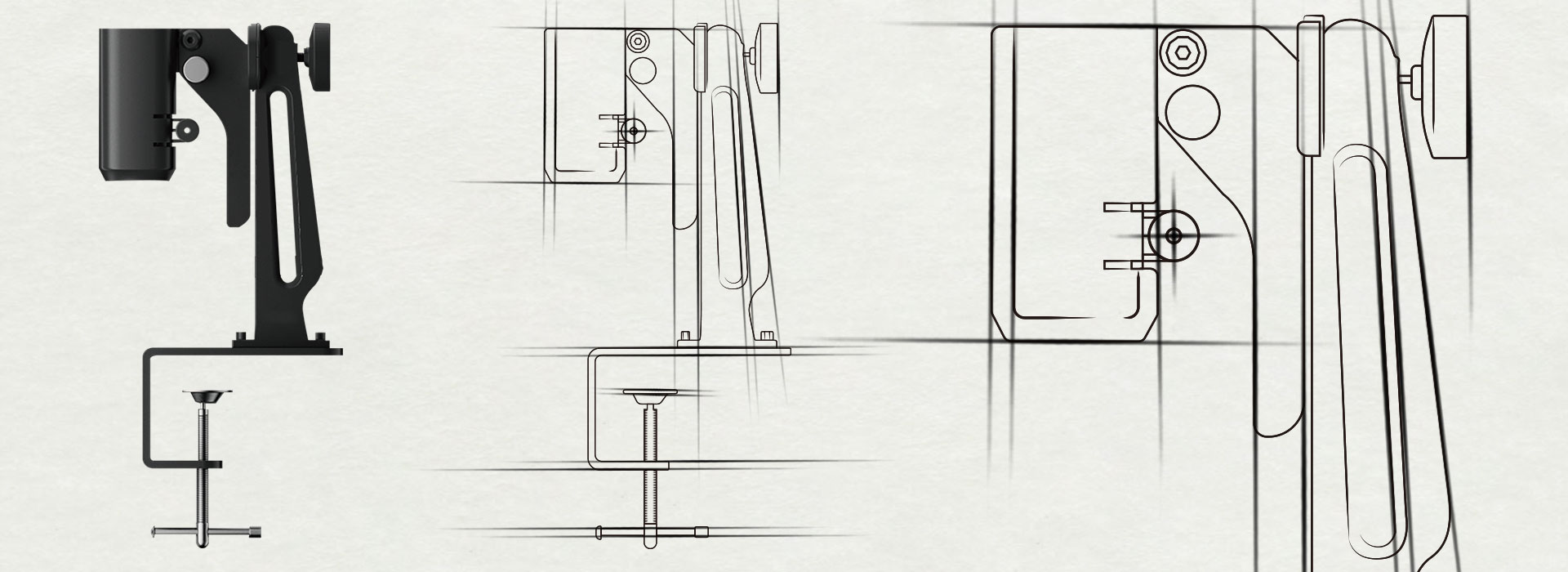

Upcoming Brand Product Initiatives

Focused on user needs, we address demands for precision and energy efficiency in varied scenarios. We keep refining R&D and product models.

A breakthrough cordless ultrasonic cutter is set for crowdfunding. It’ll gather real user feedback for iterative upgrades, aiming to deliver a better experience.

We’re also committed to developing supporting accessories. By expanding the ultrasonic cutter’s application boundaries, we showcase innovation, improve the product ecological layout, and build a more comprehensive, professional product system.

Introduction to Jakemy Ultrasonic Cutter

Series Y

JM – Y10 Handheld Ultrasonic Cutter & Polisher

- Function: Multi-in-One All-Round Operation

- Three-mode integration: Combines cutting, grinding, and polishing for versatile use. The ultrasonic cutter handles a wide range of materials including carbon fiber, metal, resin, and plastics. Perfect for DIY such as model making, jewelry processing, and electronic packaging.

- Professional blade system: Basic version includes a 30°fine-point blade and polishing sticks. The professional version adds 4 blade types (60°fine-point, 30°narrow point, narrow chisel, straight blade) for precision processing.

- Performance: High-Frequency & Efficient Drive

- 35W / 40kHz high-performance configuration: PZT ceramic transducer with titanium alloy booster delivers faster cutting. Smart frequency tracking keeps power stable.

- Long-lasting cooling: Dynamic heat dissipation system with Type-C fast charging prevents overheating or shutdown.

- Design: Ergonomic Optimization

- Lightweight and durable: Equipped with 179mm anodized aluminum alloy handle, DIYers find it easy to control the ultrasonic cutter with one hand.

- Smart safety: OLED screen displays mode/temperature in real time. Front LED light enhances visibility, reducing misoperation risks.`

- Convenience: Details that Enhance Experience

- User-friendly control: Mode button & inching switch with Auto/segmented modes. Includes child lock and blade storage compartment for safety.

- Type-C fast charging works with power banks. The Jakemy ultrasonic cutter is more efficient than traditional tools, making it ideal for DIYers at home or on the go.

- Additional Advantages

- Low-threshold procurement: Low MOQ, free samples available. Supports OEM customization (logo, packaging). CE-certified for reliability.

- Works as a multifunctional Jakemy ultrasonic cutter and polisher, with applications from ultrasonic glass cutter work to ultrasonic cutter for 3D print post-processing and polishing.

- Function: Multi-in-One All-Round Operation

- Three-mode integration: Combines cutting, grinding, and polishing for versatile use. The ultrasonic cutter handles a wide range of materials including carbon fiber, metal, resin, and plastics. Perfect for DIY such as model making, jewelry processing, and electronic packaging.

- Professional blade system: Basic version includes a 30°fine-point blade and polishing sticks. The professional version adds 4 blade types (60°fine-point, 30°narrow point, narrow chisel, straight blade) for precision processing.

- Performance: High-Frequency & Efficient Drive

- 35W / 40kHz high-performance configuration: PZT ceramic transducer with titanium alloy booster delivers faster cutting. Smart frequency tracking keeps power stable.

- Long-lasting cooling: Dynamic heat dissipation system with Type-C fast charging prevents overheating or shutdown.

- Design: Ergonomic Optimization

- Lightweight and durable: Equipped with 179mm anodized aluminum alloy handle, DIYers find it easy to control the ultrasonic cutter with one hand.

- Smart safety: OLED screen displays mode/temperature in real time. Front LED light enhances visibility, reducing misoperation risks.`

- Convenience: Details that Enhance Experience

- User-friendly control: Mode button & inching switch with Auto/segmented modes. Includes child lock and blade storage compartment for safety.

- Type-C fast charging works with power banks. The Jakemy ultrasonic cutter is more efficient than traditional tools, making it ideal for DIYers at home or on the go.

- Additional Advantages

- Low-threshold procurement: Low MOQ, free samples available. Supports OEM customization (logo, packaging). CE-certified for reliability.

- Works as a multifunctional Jakemy ultrasonic cutter and polisher, with applications from ultrasonic glass cutter work to ultrasonic cutter for 3D print post-processing and polishing.

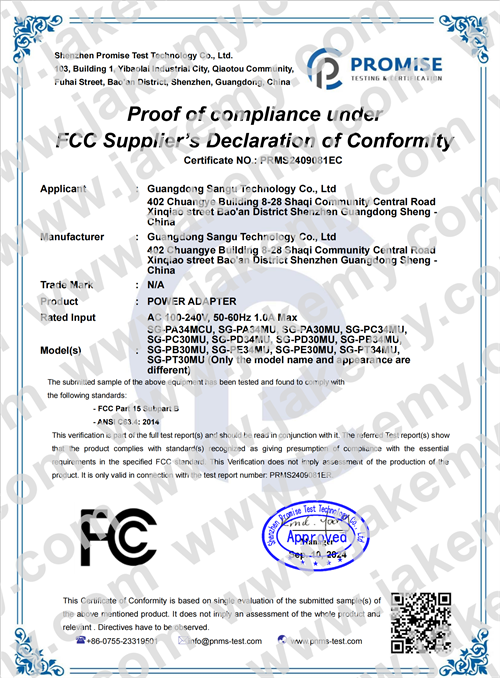

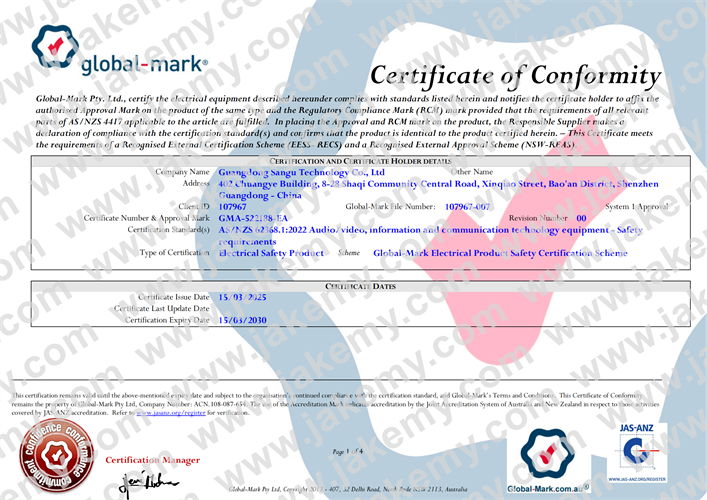

Certificate Support

Our products have obtained a variety of authoritative certificate certifications. These certificates are not only a strong proof of product quality but also show our strong product manufacturing strength to enterprise-level potential partners.

Company Introduction

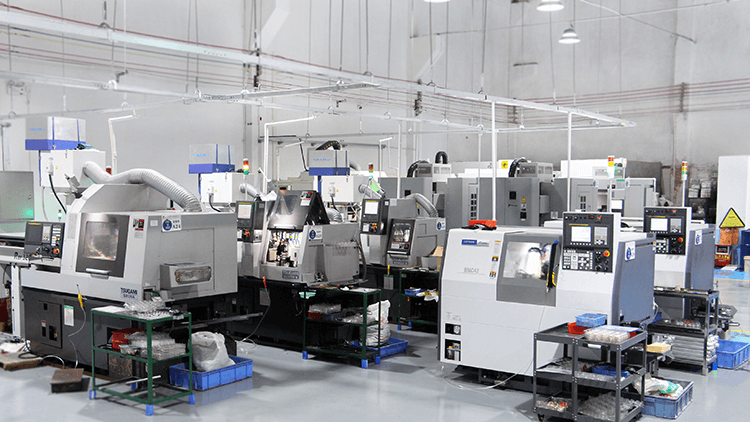

With strong factory support, Jakemy ensures high cost performance, stable quality, mass supply, and efficient delivery of its products. Our main advantages are:

- Technological Innovation

Backed by a professional R&D team, Jakemy continuously develops advanced tools such as the Jakemy ultrasonic cutter. From precision screwdrivers to ultrasonic cutter for 3D print finishing, our innovations meet diverse market demands.

- Production Guarantee

Our own factory allows strict quality control and efficient operations, ensuring every ultrasonic cutter meets international standards.

- Brand Advantage

Jakemy has earned a solid market reputation as one of the trusted ultrasonic cutter manufacturers and suppliers, offering reliable OEM & ODM solutions.

- Good Service

Our professional sales team provides complete service—from consultation to after-sales support—ensuring customers choose with confidence.

With the strong support of its own factory, Jakemy has achieved high cost performance, stable quality, mass supply, and efficient delivery of products. The specific advantages are as follows:

- Technological innovation.

- Production guarantee.

- Brand advantage.

- Attentive service.

FAQ

I. Procurement and Customization

- Q: Are samples free?

A: New customers may request 1–2 free samples but must cover shipping costs. - Q: Besides CE certification, do you support other international certifications?

A: Yes. In addition to CE, we also hold FCC and RoHS certifications. For other certifications, please contact our customer service team.

II. Technology and Performance

- Q: How do you ensure performance consistency when purchasing in bulk?

A: The Jakemy ultrasonic cutter undergoes strict quality inspections before shipment. Third-party inspections are also available (costs borne by the customer). - Q: What is the service life of the SK5 high-carbon steel blade? Is there a bulk discount?

A: Blade life depends on user habits and frequency of use. Discounts for bulk orders of blades are available—please contact customer service for details.

III. Logistics and Delivery

- Q: What is the typical production cycle? Which shipping methods are supported?

A: Standard wholesale orders ship in 7 working days. OEM/ODM orders take 7–20 days depending on customization. We support DHL, UPS, and sea freight options. - Q: Do you provide commercial invoices and packing lists for customs clearance?

A: Yes. English invoices and packing lists are included with all orders to assist with customs clearance (tariffs borne by the customer).

IV. Price and Payment

- Q: Are discounts available for larger quantities?

A: Yes. Prices are tiered by order volume, customization requirements, and payment method. Larger orders of ultrasonic cutters or B2B bulk purchases secure better pricing. - Q: What payment methods do you support?

A: Multiple payment options are available. For details, please contact our customer service team.

Suggestion: You can provide company information (such as industry, purchase quantity) via email (yifengjakemy@gzyftools.com) to obtain a customized quotation; for bulk orders, it is recommended to arrange sample testing first to confirm that the performance meets production requirements before placing an order.

WHAT ARE YOU WAITING FOR…

Get Factory Price

Our primary focus is to place our customers at the forefront, guiding them in selecting the ideal screwdriver tool kits. Our specialized precision screwdriver options are crafted to cater to the distinct requirements of each customer.

OUR LOCATION

Wan Ke Li hardware factory No. 10 Huanzhen East Road, Yanbu, Dali Town, Nanhai District, Foshan City, Guangdong Province, China

CONTACT

yifengjakemy@gzyftools.com

Jakemy Reserves All the Right for Final Explanation